List of Works A-Z

1. Features

Our company was originally engaged in the shipbuilding industry in the port of Kesennuma. With the local fishing industry entering the hard times we decided to launch a new business in a different field - applying technologies use in shipbuilding to architecture. We involve through planning and production to construction. We create complicated curved steel structures and design and produce complex 3-dimensional structures. Our original shipbuilding technology is divided into four categories.2. Management Principles

3. Business Overview

| Company | Takahashi Kogyo Co., Ltd |

|---|---|

| President | Kazushi Takahashi |

| Location Head Office / Factory |

38-4, Uchinuma, Hajikami, Kesennuma-shi, Miyagi-ken, 988-0247, Japan Tel: 81-226(27)3943 / Fax: 81-226(27)4613 |

| Established | 10/ 06/ 1985 |

| Capital Stock | 20,000,000 Yen (approx. $200,000) |

| No. of Employees | 10 |

| Banking Relationship | Kesennuma Shinkin Bank、77Bank |

| Certification ISO9001 (JMAQA-925) |

Registered Products/ Service Coverage JIS Q9001:2000/ISO9001:2000 Metallic Structure、Steel Construction、Incineration Equipment, Metal Tank Design/ Production/ Setting. Building Operations、Engineering Work Design/ Construction Practice. |

| Construction Licenses | Miyagi Prefecture Governor License (soil, construction, steel) and 17 other categories. |

| Business Items | Design and building metal constructions created from a fusion of shipbuilding technology and traditional architecture; water gate facility fortification (aluminium alloy, stainless); ship construction; restoration of equipped ship (Steel, aluminium alloy); metal plants; can manufacturing; pipe laying work; general architecture and civil engineering work. |

4. History

| Jun-85 | For the purpose of ship structure repair and steel building construction work, Takahashi Kogyo established with 3,000,000 Yen (approx. $30,000) capital. |

|---|---|

| Oct-89 | ew Factory established in Hajikami, Kesennuma-shi. |

| Mar-91 | With a view to moving to working on land, expansion of the plant and processing equipment. |

| Dec-96 | Main office and factory moved to Kesennuma factory. |

| Jan-97 | Capital increased to 10,000,000 Yen (approx. $100,000). |

| Jul-00 | Organization changed to a Limited Company and capital increased to 15, 000,000 Yen (approx. $150,000). |

| Jan-01 | ISO9001 certification acquired. |

| Oct-01 | Ministry of Land, Infrastructure, Transport and Tourism certification for steel structure fabrication (M Grade). |

| May-07 | Ginza Office established in Minato-ku, Tokyo. |

| Feb-8 | Capital increased to 20,000,000 Yen (approx. $200,000). |

5. Awards

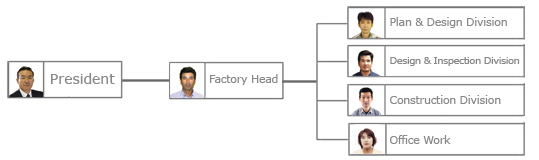

6. Management Structure

Factory Scale

| Total Area | 4100㎡ |

|---|---|

| Layout | A three-storey factory partly constructed from steel and an office. (Total floor space: 880㎡) |

| Plant + Shed | larger steel construction (450㎡)/ With a smaller steel construction (180㎡) |

| Material Yard | 850㎡ |

Engineering Managers

| Building Construction Engineering Manager | Class 1 - 2 Workers/ Class 2 - 3 Workers |

|---|---|

| Construction Management Engineers | Class 2 - 3 Workers |

| Weld Engineering Manager (WES8103) | Class 1 - 1 Worker/ Class 2 - 5 Workers |

| Welding Coach (WES8107) | Class 1 - 1 Worker |

| Steel Fabrication Engineering Manager | Class 1 - 2 Workers/ Class 2 - 4 Workers |

| Steel Fabrication Inspector | 3 Workers |

| Steel-frame Ultrasonic Wave Inspector | 1 Worker |

| Non-destructive Inspector (NDI-UT) | Class 1 - 2 Workers |

| High-strength Bolting Connection Manager | 4 Workers |

| Head Shipbuilder | 2 Workers |

| Design & CAD (Computer Aided Design) Drawing Technician | 4 Workers |

Technical Experts

| Semi Automatic Welding Engineer (JISZ3841)-(SN-2FH,SA-3FH) | 9 Workers |

|---|---|

| Arc Welding Engineer (JISZ3801)-(N-2FH,A-2FH) | 9 Workers |

| Stainless Welding Engineer (JISZ3821)-(TN-F) | 2 Workers |

| Aluminium Welding Engineer (NK)-(T-A2F), (NK)-(S-A2F,H) | 8 Workers |

| Iron Engineering Technician (Steel Structure) | Class 2 - 3 Workers |

| Gyotestu (Plate Forming) Shipbuilder | 2 Workers |

Major Facilities

| Overhead Travelling Crane (2.8 ton) | 5 | Positioner | 1 |

|---|---|---|---|

| Outside Travelling Crane (2.8 ton) | 1 | Roll-bending Machine (6mm) | 1 |

| Band Sawing Machine (700H) | 1 | Manual Arc Welding Machine | 9 |

| Guillotine Shearing Machine (13mm) | 1 | Gouging Machine | 5 |

| Oil Press (250 ton) | 1 | Plasma Cutting Machine | 2 |

| Drill Press | 6 | Supersonic Flaw Detector | 1 |

| CO2 Semi Automatic Welding Machine | 20 | Film Thickness Gauge | 2 |

| TIG Welding Machine | 2 | CAD System (2D, 3D) | 7sets |

| MIG Semi Automatic Welding Machine | 4 | Other Machines | 1set |

Other

| Publication of patent applications | (2000-160817) Construction of double flooring with under floor wiring using FRP form. |

|---|---|

| Patent application | (2004-055048) A way of producing a new building material, which contains transparent parts. |

| Research and Development | 1998 Miyagi Creating Technology Assistant Industry ) Simple approach thick small diameter pipe semi automatic welding machine. |